6-20 个字符(仅限字母加数字)

密码不一致

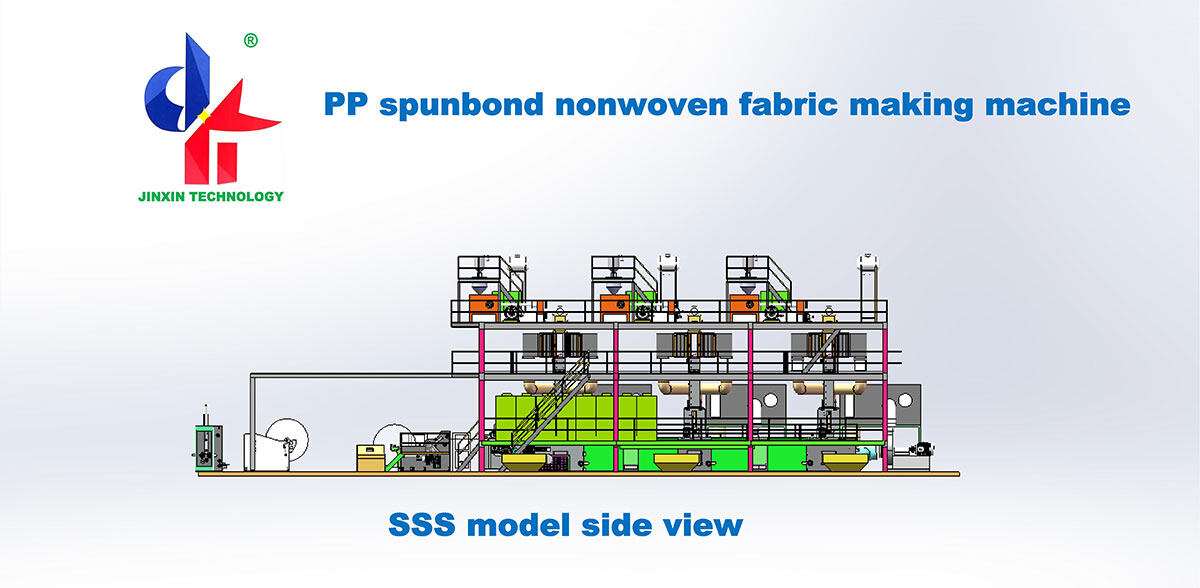

SSS nonwoven machine production line

Safety Measures for Running a Spunbond Non-Woven Production Line:

During the production process, the spunbond nonwoven fabric production line must pay close attention to certain operational elements and placement positions. If we utilize the equipment incorrectly, it could result in significant equipment accidents or even machine damage. The production line for spunbond nonwovens has the following operating precautions.

| Model | JX-SSS | ||

|---|---|---|---|

| Product Width | 1600mm | 2400mm | 3200mm |

| Equipment Size | 40*15*12m | 40*18*12m | 40*20*12m |

| Mechanical Speed | 400m/min | 400m/min | 400m/min |

| Gram Weight | 10-150g/m2 | 10-150g/m2 | 10-150g/m2 |

| Daily Output | 10-16T/Day | 14-24T/Day | 20-30T/Day |

| Transformer Capacity | ≈500KVA | ≈700KVA | ≈900KVA |

| Power Consumption | 520°-850°Ton | 520°-850°Ton | 520°-850°Ton |

About Us

Fujian Jinxin Machinery Technology Co.,Ltd. was found in 2007.Our company offers variety of products which can meet your multifarious demands.We adhere to the management principles of "quality first, customer first and credit-based" and always do our best to satisfy potential needs of our customers.

We mainly produce S,SS,SSS,Meltblown,SMS,SSMS,SMMS,SSMMS,PLA,PET series nonwoven machine and laminating machine.

1.Medical: mask, protection gowns, bed sheets,drapes,shoe coves and etc.

2.Hygiene: children diaper, adult diaper, women care products and etc.

3.Packaging: shopping bags,clothes bags and etc

4.Other uses: crop protection cloth, tea bags , filter materials, lampshades, etc

Our Factory

Our product is quality proven,superior in design and produced as per the highest quality standards.Before leaving our factory,it is tested and retested for performance,productivity and durability.Through our continuous research and development, advanced skills, and a strong commitment to customer service,we are taken as a dependable supplier of China.No matter whether you are looking for a single machine or a whole production line,you can get outstanding machine and know-how results from us.Because of good quality and service,we have won a good reputation among domestic and international customers.

We hope to establish good and long-term business cooperation with customers all over the world. If you have any inquiries about our products, please feel free to contact us.

Precautions For The Operation Of Spunbond NonWoven Production Line

Spunbond nonwoven fabric production line needs to pay attention to the placement position and some details in the operation process during the production process. If we operate improperly, it may cause damage to the machine, or even serious, equipment accidents. The following are the operating precautions for the spunbond nonwoven production line.

Where to place the machine

(1) It cannot be placed in a non-horizontal position. when you install the spunbond nonwoven fabric machine on a horizontal surface, you should use the product conveying plane as a reference to make the machine level. To install the machine horizontally, place a level on the reference plane (that is, the plane on which the product is conveyed).

(2) It cannot be placed in direct sunlight. Installing the machine in a place with direct sunlight or strong light will cause the photoelectric switch to fail.

(3) It cannot be placed in a place with an earthquake source or in a place where the space is too narrow.

(4) It cannot be placed near the air outlets of ventilation equipment and air conditioners.

(5) The harsh environment such as corrosive gas or dust is not suitable for the use and maintenance of spunbond nonwoven production line.

Points for attention in the operation of the machine

1.Before use, we need to check whether the spunbond nonwoven machine is faulty. If any fault is found, we should immediately respond to the relevant personnel. The main thing is to check and adjust the conveying speed when the conveying motor is turned on so that the machine can operate quickly.

2.In the process of feeding, we must pay special attention to the loading range of the machine. If it exceeds the load range of the machine, it is easy to damage the mechanical equipment, so we must pay attention to it.

3.In the process of processing, we often add reagents to the spunbond nonwoven fabric production line. Remember that the reagent water level cannot exceed the highest height of the machine. When the mechanical water tank level is lower than the suction height of the submersible pump, water should be added in time.

After operating the spunbond nonwoven fabric machine, we also need to check and maintain it frequently, and repair or replace it in time when it is found that the parts are worn or malfunctioning, to extend the service life of the machine. If you want to know more about the spunbond nonwoven production line after reading the above content, you can contact us for related solutions.